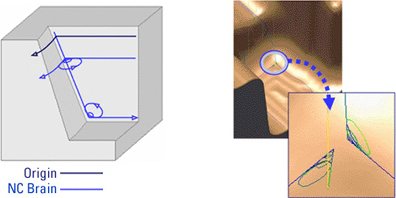

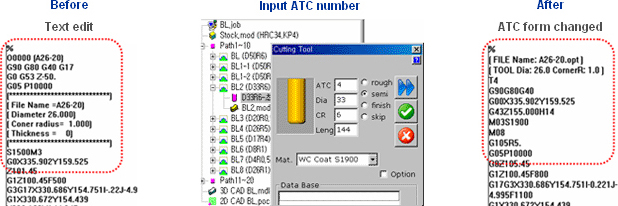

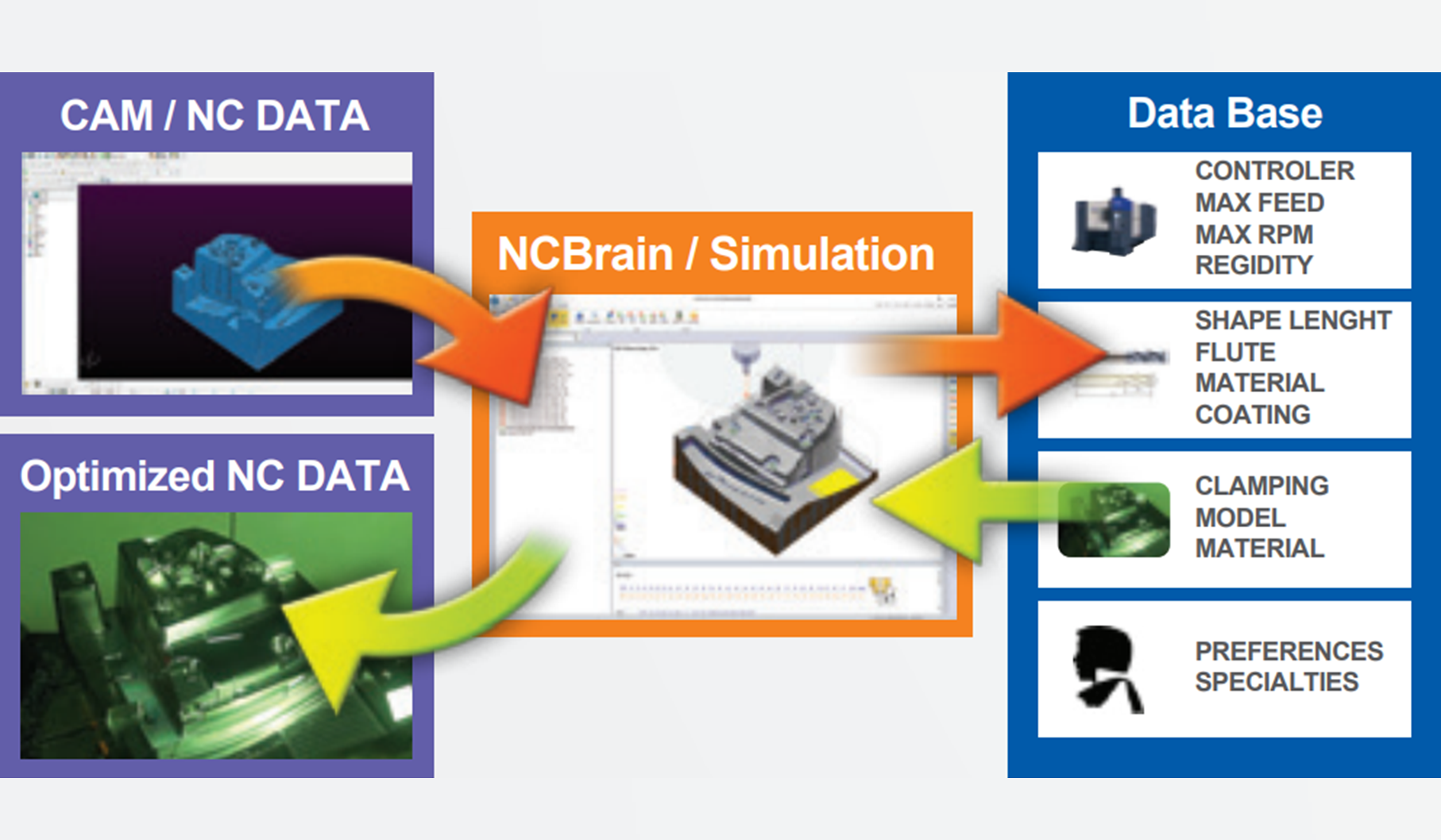

What is NCBrain? NCBrain builds the best database in consideration of machine specifications, tools, stock, and cutting conditions of items. Also the existing NC data is changed to optimized NC data such as controlling the machining feed-rate and adding tool-path through simulation by the database.

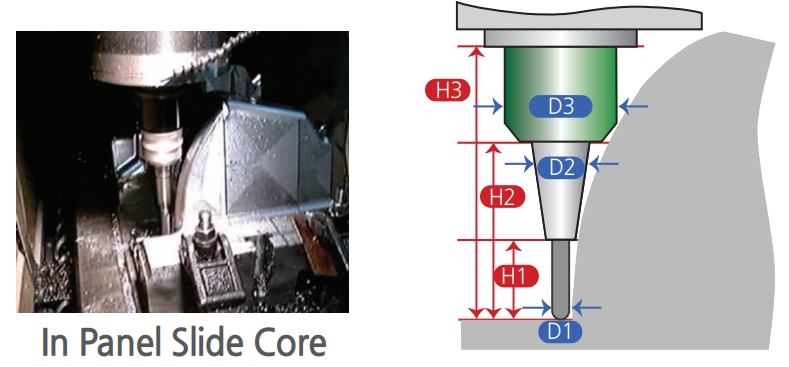

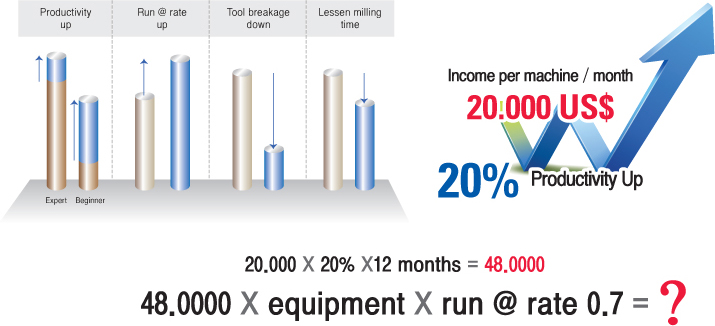

Experience the Efficiency of Mold Machining

-

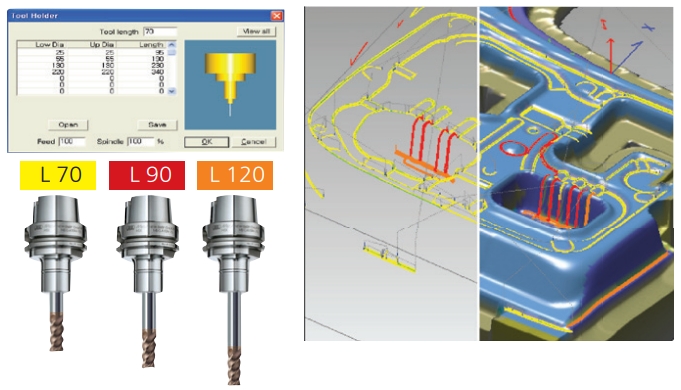

Database for Optimal Selection of Cutting Conditions

By simulating the NC data created by CAM, it can be machined under optimal cutting conditions.

-

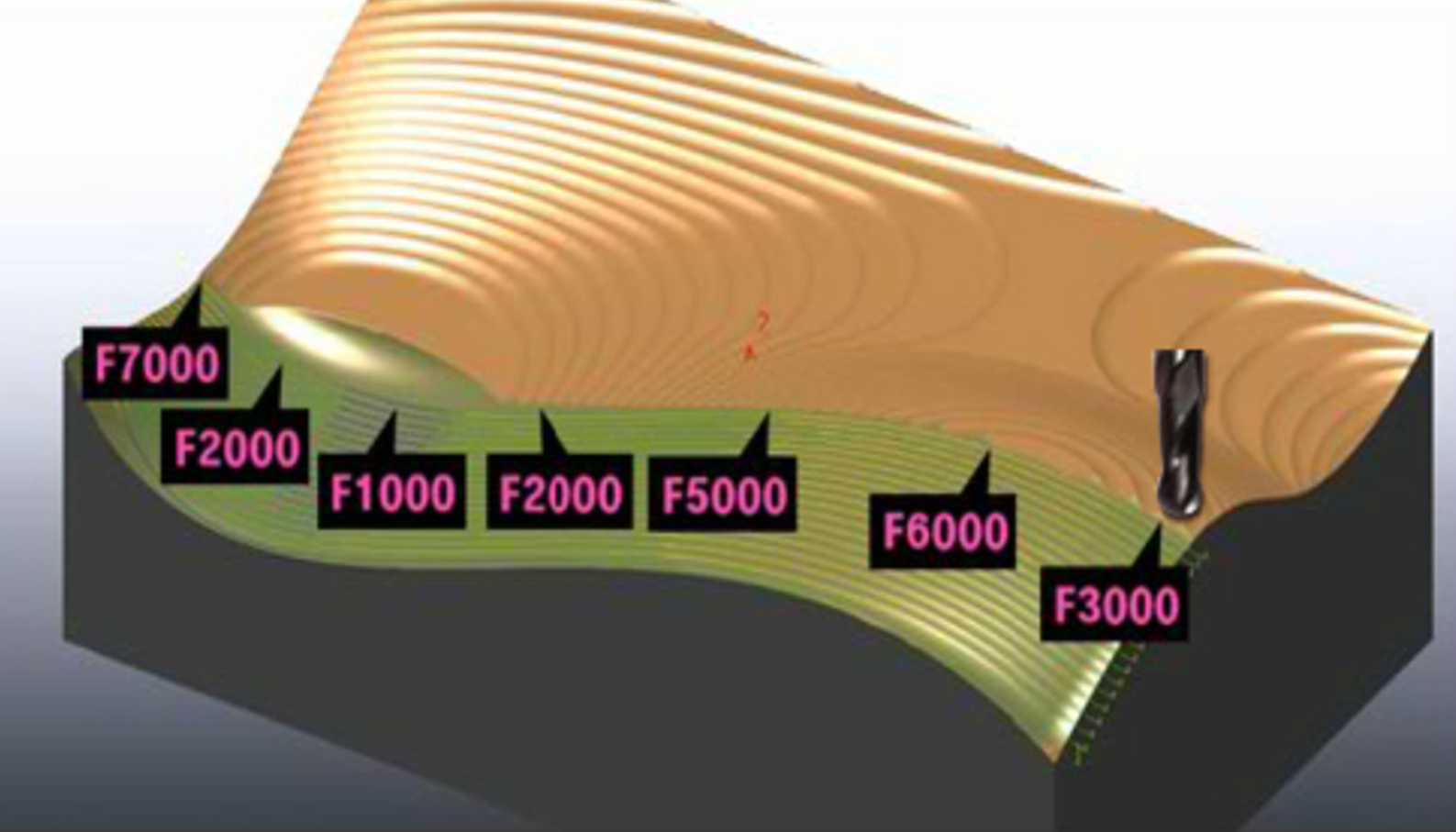

Control of Feed & Spindle

Since the machining load is different depending on the shape, the optimum feed rate is given to each machining section to minimize machining time and tool breakage.

-

Tool-path deletion of no-load and air-cut area

It reduces machining time by deleting areas where the tool is operated in the air, such as air cut, no-load, and G0 height sections.