- Smart Technology

- Smart Technology Notice: Undefined offset: 2 in /home/host/ncbrain/www/html/_skin/layout/inc_navigation_middle.php on line 60 Notice: Undefined offset: 2 in /home/host/ncbrain/www/html/_skin/layout/inc_navigation_middle.php on line 86 Notice: Undefined offset: 3 in /home/host/ncbrain/www/html/_skin/layout/inc_navigation_middle.php on line 86

SMART TECHNOLOGY Four smart technologies of NCB required for mold NC machining

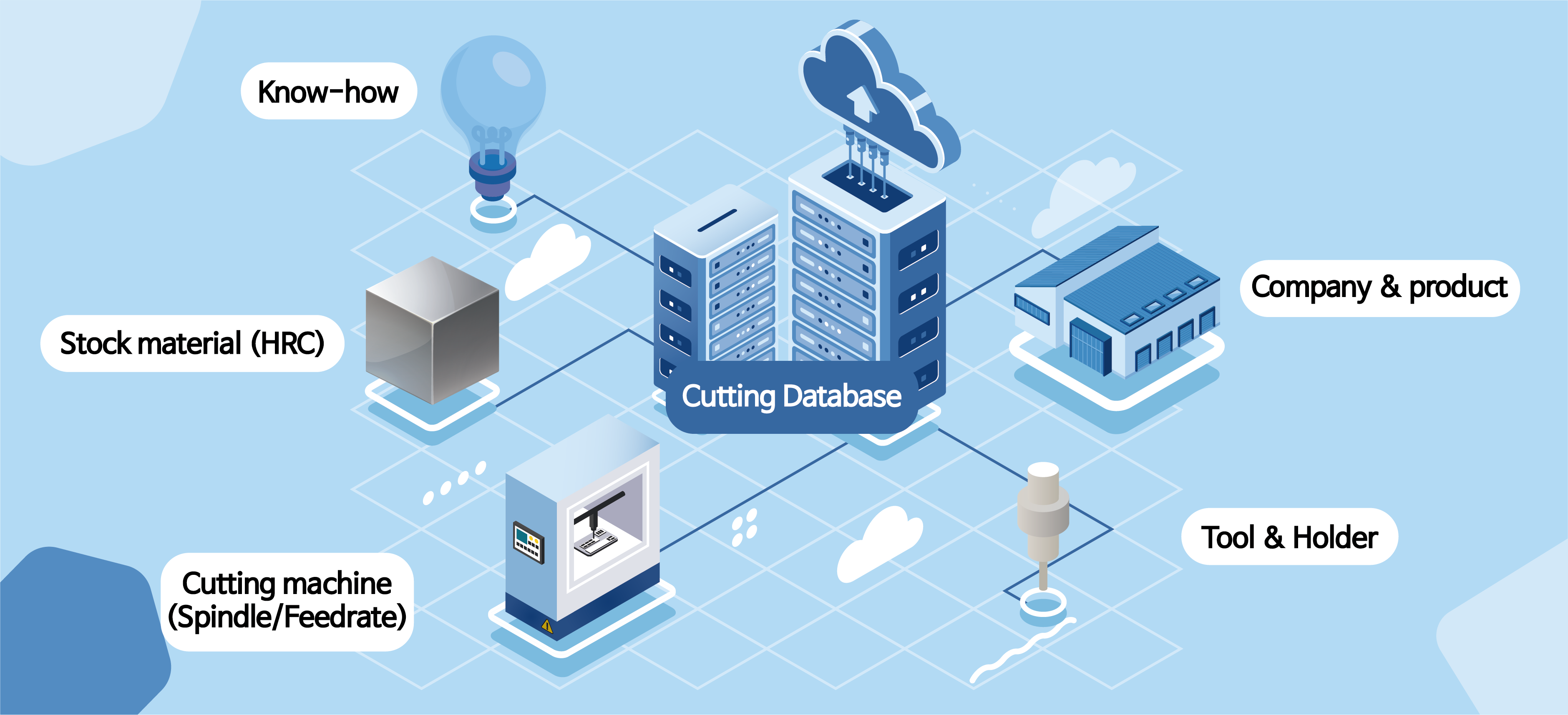

STEP1 Database

Builds your company's own technical know-how According to the product, machine, material, tool and machining method as a database.

This raises and standardizes the level of your company's Mold industry by analyzing and managing the machining tendency.

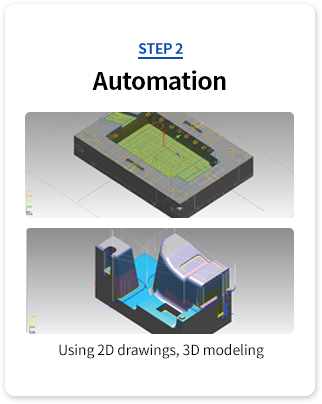

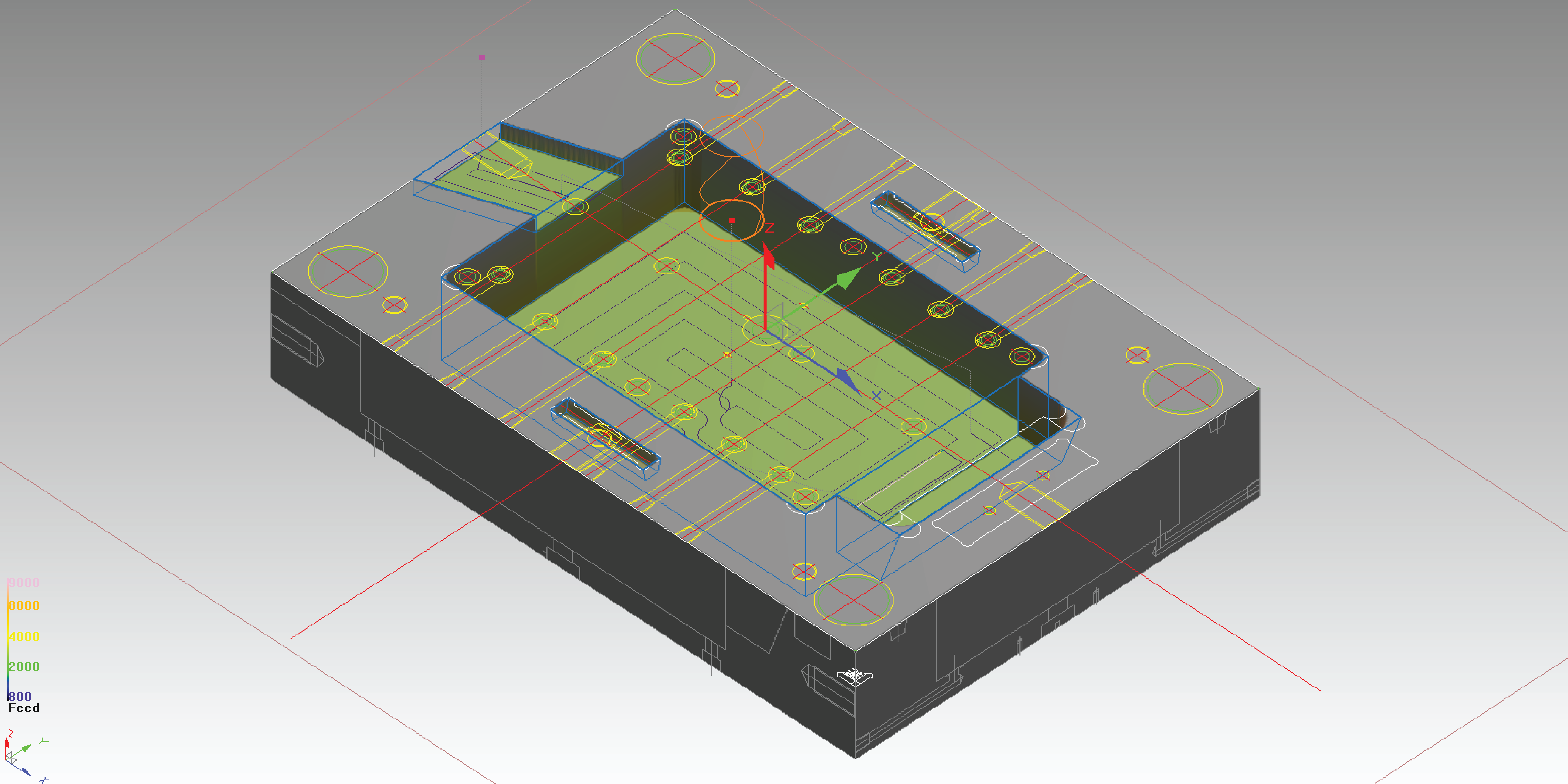

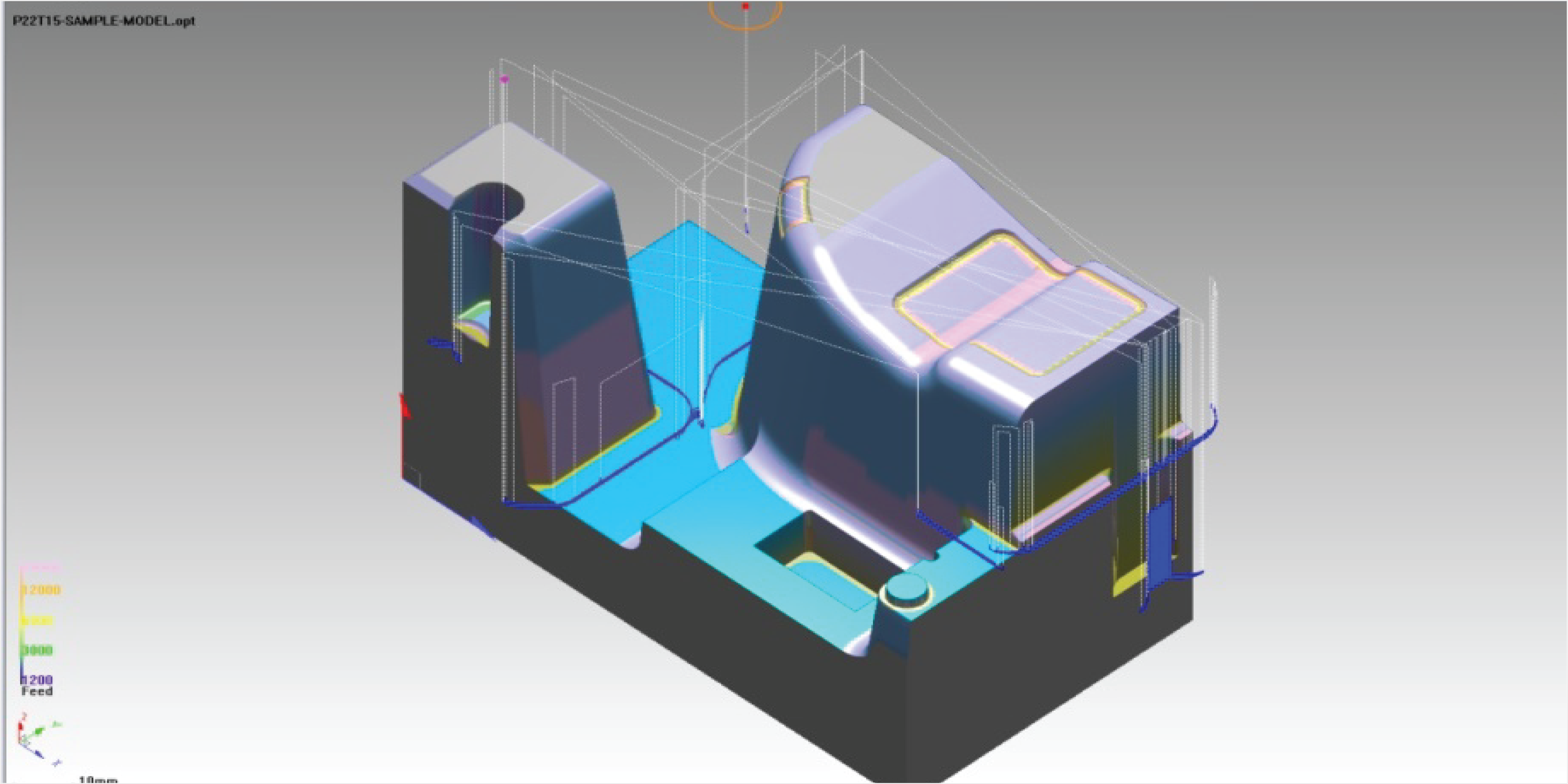

STEP2 Automation

It is possible to create and modify NC data with a simple click of the 2D CAM mold base. And if there is only 3D modeling, CAM data is created through dedicated holder and tool. In addition, it supports machining with the desired tool in the desired area.

-

NCBrain 2D CAM

Supports for 2D/3D drawing files (DXF, DWG) -

NCBrain AICAM

Support for 3D modeling files (x_t, stl)

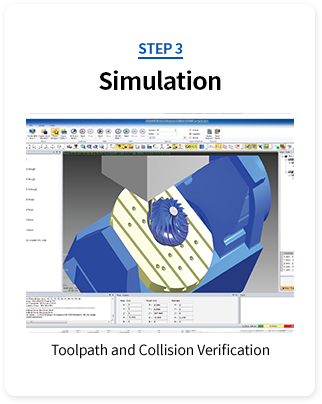

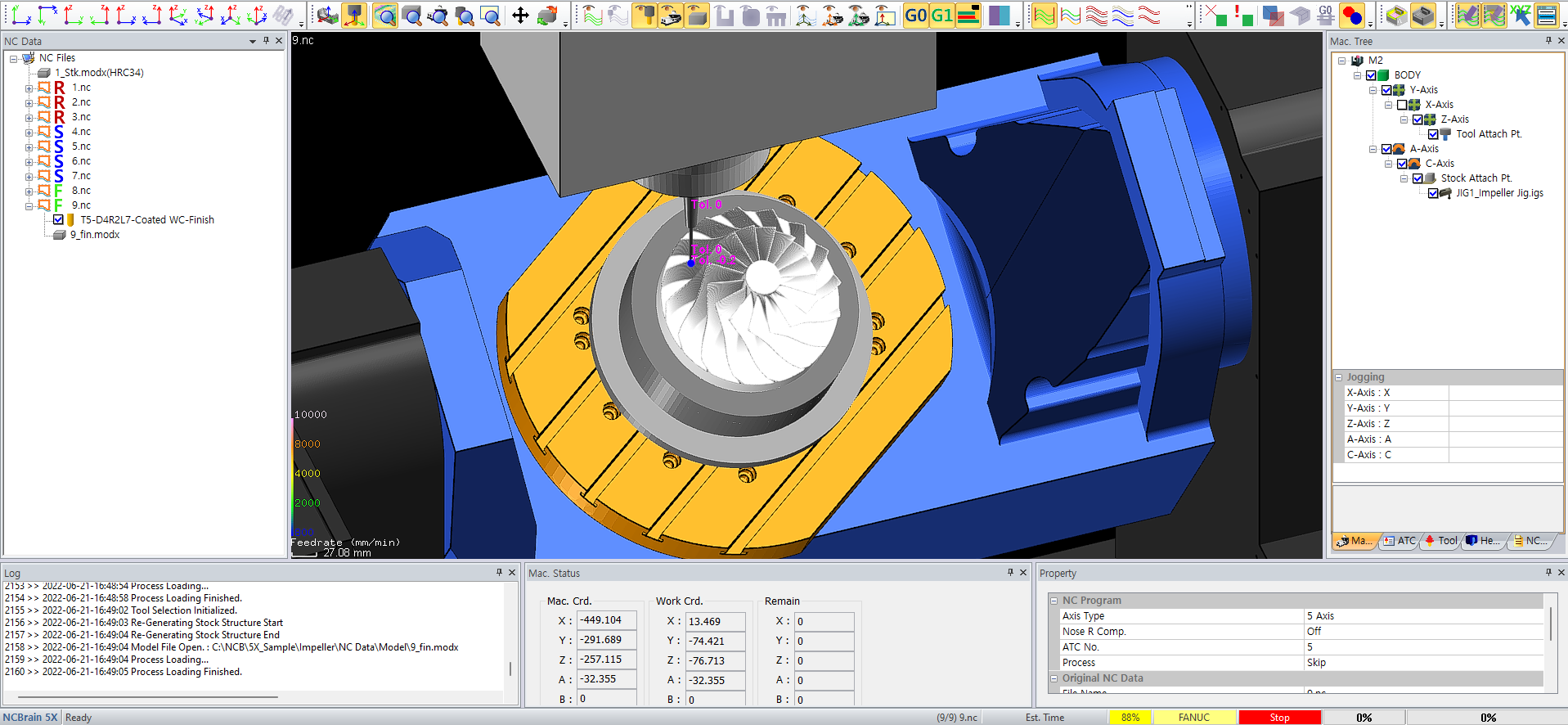

STEP3 Simulation

In simultaneous 5-axis to 3-axis machining, error and collisions with machine parts, tools, holders, materials, etc. are verified through the same simulation as the actual machining, and machining efficiency is improved.

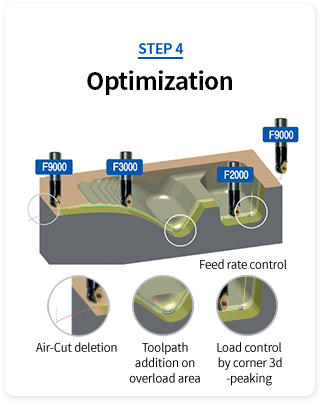

STEP4 Optimization

By simulating NC data with database, it is changed to optimized NC data.

-

01

Efficiency

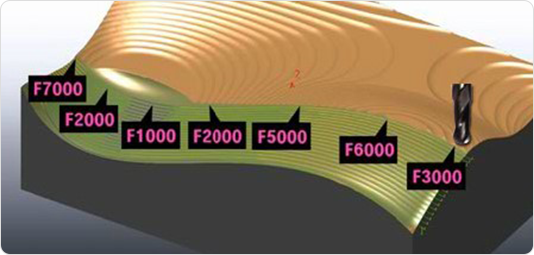

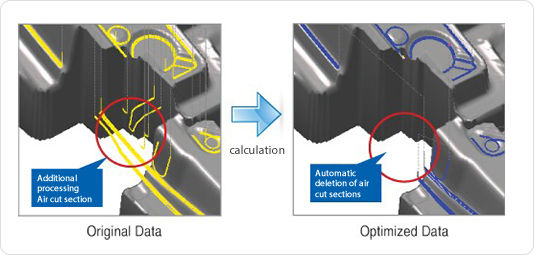

As the machining load changes depending on the shape, the optimized feed rate for each section is changed, and the tool-path is automatically deleted in the air-cutting section or section with little amount of cutting, thereby shortening the machining time for efficient machining.

Feed rate control by section

Delete few-load toolpath

-

02

Safety

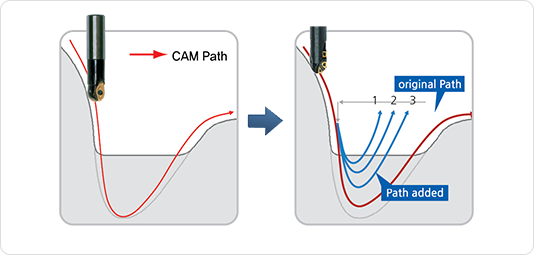

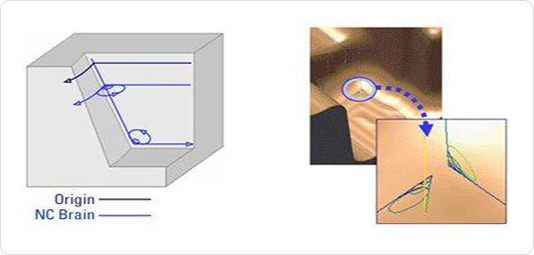

Overload is the most common cause of tool breakage during machining. While calculating the cutting volume as the tool moves, toolpaths are automatically added in overloaded sections such as corners and planes. This ensures safe machining by preventing tool breakage or poor quality machining.

Add Z-pitch toolpath

Add corner 3d-peaking toolpath